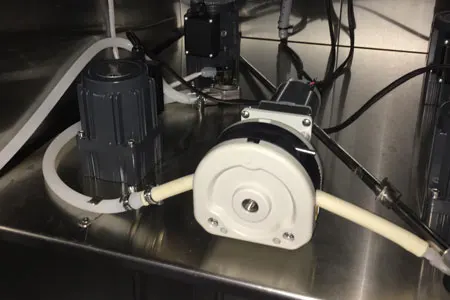

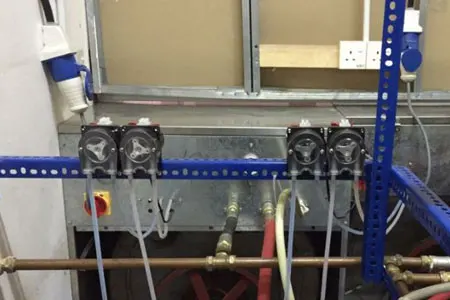

Chonry Peristaltic Pump

Peristaltic pump application field

Chemical industry; Mining and metallurgy industries; Paper industry; Paint coating industry; Food industry; Ceramic industry; the Oil industry; Water treatment industry; Pharmaceutical industry; Medical device industry;

Pharmaceutical industry application: the application of peristaltic pumps in the pharmaceutical industry is mainly used for drug coating granulation and liquid dispensing. Spray drying granulator is also called dry granulator and fluidized bed granulator, which is used to spray special icing on the surface of various particles and form particles after drying. This pelletizer itself specific dry heat source, can play the purpose of evaporation of water, but water evaporation and particle formation is a dynamic relationship, so the amount of liquid and water need to be sprayed into the very precise, to ensure a certain humidity of particles to facilitate the perfect formation of particles.

Peristaltic pump classification:

The peristaltic pump is used to obtain the required flow, so according to the operation and use of the peristaltic pump, it is divided into:

1. Speed-regulating peristaltic pump: with basic control functions of peristaltic pump, display speed, start and stop, direction, speed adjustment, filling and emptying, power-off memory, external control input, and other functions.

2, flow type peristaltic pump: in addition to the basic function, increase the flow display, flow correction, communication, and other functions.

3, distribution peristaltic pump: in addition to the basic control function, increase the flow display, flow correction, communication, liquid distribution, suction, output control, and other functions.

4, customized (OEM) peristaltic pump: with a series of different flow ranges of the peristaltic pump head, customers can according to their own equipment needs, design different peristaltic pump drive circuits supporting use.

Daily maintenance

In the process of daily use, after using for a long time to change the hose as far as possible, so that it is not easy to cause the silicone tube rupture, fluid from the tube within the limited capacity of flow into the pump head roller with corrosive liquid into the roller gap, wash immediately remove will pump to avoid weathering after solidification in the roller gap, will cause the pump head stuck phenomenon. The hose should be replaced in time according to the use frequency of the specific pump, or the position should be moved frequently. If the liquid is highly corrosive, please choose the inlet hose of the corresponding material to avoid damage to the pump

0users like this.